BioResources

- About the Journal

- Authors & Reviewers

- How to Self-Register

- Full Site Navigation

- Editorial Board

- Meet the Staff

- Editorial Policies

- General Instructions

- Ethics & Responsibilities

- Article Preparation

- Submission Instructions

- Acknowledgment of your Peer-Reviewing

- Writing Style Suggestions

- Reviewer Guidelines

- Back and Current Issues

- Scholarly Reviews

- Special Conference Collection Issues

- Competition Print Edition

- FRC: Pulp and Paper Fundamental Research Symposia Proceedings

- Paper Manufacturing Chemistry

- BioResources Early Career Investigator Award

- Distance Education: Online Masters Degree & Individual Courses

- Upcoming Conferences

- Hands-On Courses

- Affiliate Journal

Evaluation of paper straws versus plastic straws: Development of a methodology for testing and understanding challenges for paper straws

New alternatives to plastic straws are being considered due to consumer demands for sustainability and recent changes in government policies and regulations, such as bans on single-use plastic products. There are concerns regarding paper straw quality and stability over time when in contact with beverages. This study evaluated the performance and properties of commercially available paper straws and their counterpart plastic straws in various intended applications. The physical, mechanical, and compositional characteristics, as well as the liquid interaction properties of the straws, were determined. The paper straws were composed mainly of hardwood fibers that were hard sized with a hydrophobic sizing agent to achieve a contact angle of 102° to 125°. The results indicated that all the evaluated paper straws lost 70% to 90% of their compressive strength after being in contact with the liquid for less than 30 min. Furthermore, the paper straws absorbed liquid at approximately 30% of the straw weight after liquid exposure for 30 min. Increased liquid temperatures caused lower compressive strengths and higher liquid uptake in the paper straws. This report provides directions and methods for testing paper straws and defines current property limitations of paper straws relative to plastic straws.

Full Article

Evaluation of Paper Straws versus Plastic Straws: Development of a Methodology for Testing and Understanding Challenges for Paper Straws

Joseph N. Gutierrez, Aidan W. Royals, Hasan Jameel, Richard A. Venditti, and Lokendra Pal *

Keywords: Paper straws; Plastic straws; Tensile strength; Compressive strength; Longevity

Contact information: Department of Forest Biomaterials, North Carolina State University, Campus Box 8005, Raleigh, NC 27695-8005 USA; *Corresponding author: [email protected]

INTRODUCTION

Straws provide a simple solution for drinking beverages more conveniently, which makes straws an excellent example of an item people take for granted. Currently, straws are massively consumed. The estimated disposable plastic straw consumption in the US is between 170 million to 490 million straws per day or 63 billion to 142 billion straws per year (Chokshi 2018).

Since the use of straws dates so far back, an accurate time and place of the first usage are impossible to determine. The earliest evidence of straw use was found in a Sumerian tomb dating back to 3000 B.C. The tomb seal showed two men drinking beer from a jar using a tube made of gold (Thompson 2011). In the 1800s, straws became popular and were made of ryegrass, a biodegradable material, which tended to change the flavor and disintegrate into the drink, leaving sediment at the bottom (Smith 2017). Paper, another biodegradable material, replaced ryegrass to solve these issues. Paper straws were the best option for several decades, but the straws still had one problem: they were not durable enough and lost their physical integrity and compressive strength. Thus, they easily collapsed once wet.

In the 1960s, the usage of plastic as a novel material changed the paper straw market to a point where no paper straws were produced after 1970 (Smith 2017). Plastics are remarkable materials with a wide variety of properties and are durable, inert, and moldable. The problem arose when plastic became a single-use, disposable material on a daily basis. The world produces more than 400 million tons of plastics every year, and 36% is destined for single-use materials, such as packaging, which in turn generates 300 million tons of waste (UNEP 2018). Of that amount, only 9% is recycled, 12% is incinerated, and the remaining 79% accumulates in landfills and dumps or is littered in the environment, with half of this amount coming from packaging waste (Geyer et al . 2017).

This amount of waste generates pollution and other environmental problems. Plastic pollution in oceans chokes and entangles sea life. It is also linked to diseases on coral reefs, as well as decreases in the reproduction and population growth of zooplankton (Ocean Conservancy 2017). Plastic products do not biodegrade, and instead, these materials break down into smaller pieces that can be consumed by organisms, putting them at risk (Shah et al . 2008; Eagle et al . 2016). Seabirds, marine turtles, and cetaceans are included among the 267 species most affected by plastic ingestion (Haetrakul et al. 2009; Simmonds 2012; Eagle et al . 2016).

Plastic litter in the ocean has been reported since the early 1970s, but it only started to draw attention from the scientific community in the last 25 years (Andrady 2011). Activism against single-use plastic, particularly plastic straws, started in 2015 after videos arose of a turtle with a plastic straw in its nose and because of media interest in the garbage patch in the Pacific Ocean (Minter 2018). Because of this, cities like Seattle, WA and Berkley, CA and big companies like Starbucks have announced the elimination of plastic straw use in the next few years (Brueck 2018; The Guardian 2018; Wootson 2018). In addition, Starbucks has announced a $10 million grant intended for the development of a global solution of a recyclable and compostable cup, claiming that the technology will be open to the public after its development (Starbucks Stories 2018).

It is important to point out that the bans need to take into account (and it is not always the case) people with disabilities, notably if the bendy (plastic) straws are banned, since many of the people depend on bendy straws to drink any beverage (Danovich 2018; Szymkowiak 2018). For this reason, a disposable plastic straw ban cannot merely be the solution to this problem. It is then necessary to have a viable alternative to plastic straws.

These market consumption changes and the increasing demand for more sustainable and environmentally friendly options to plastic have generated several alternative materials in the production of drinking straws (Smith 2017). Metal, glass, or silicon are some of the best alternatives for reusable straws. However, single-use straws made of paper are returning to the market. Even bendable straws made of paper are now available (Aardvark 2019). Several brands, mostly in China, the UK, and the US, have returned to products not seen in more than four decades (Smith 2017; BBC 2018; Sorensen and Reinke 2018).

Paper straws are once again the best option for a disposable straw to drink a beverage without the plastic waste that can last for over 500 years in the environment (UNEP 2018). Nevertheless, paper straws are still not durable enough and typically cost more than their plastic counterparts. They lose their mechanical integrity once they are in contact with a typical beverage, and some brands’ straws can change the taste of the drink (Purtill 2018).

The aim of this study was to benchmark properties of paper straw already on the market with common, single-use plastic straws to identify which properties need improvement. The tensile and compressive properties as well as their interactions with liquids of commercial paper straws were compared with plastic versions.

EXPERIMENTAL

Four commercial brands of plastic straws and three commercial brands of paper straws were used for this research (names of the brands were excluded). All plastic and paper straws were acquired through Amazon.com, Inc. (Seattle, WA, USA). Common drinking (fountain) water, Coca-Cola ( i.e. , Coke) (Atlanta, GA, USA), and Chick-fil-A (Atlanta, GA, USA) sweet tea were used as the beverages for the longevity tests. Table 1 describes each sample used.

Table 1. Straw Sample Descriptions

The determination of the weight and dimensions of the straw samples was necessary to make a proper comparison between the paper and plastic straws. The weight, length, external diameter, and thickness were measured. In addition, the internal diameter, external area, basis weight, and density of the samples were calculated. A Mettler Toledo analytical balance (PB303-S; Columbus, OH, USA) was used for the weight measurements. All tests and measurements were made under standard conditions (23 °C and 50% relative humidity (RH)) using conditioned samples according to the TAPPI T402 sp-08 standard (2013). The fold endurance test was made with an MIT #1 Folding Endurance Tester (Tinius Olsen Testing Machine Co., Horsham, PA, USA) in accordance with the TAPPI T511 om-02 standard (2008).

The fiber length of the paper in the straws was measured with a fiber quality analyzer (FQA) (FQA-360; OpTest Equipment Inc., Hawkesbury, Ontario, Canada) according to the TAPPI T271 om-07 standard (2012). The sample disintegration was completed using a pulp disintegrator (TMI 73-18; Testing Machines, Inc., New Castle, DE, USA) using 0.5 g of paper straw sample in 1 L of water at 15000 rpm for 10 min.

The mechanical and longevity tests compared the plastic straws with the paper straws. The longevity test replicated a typical usage of these products under controlled conditions. The samples were placed in water at four different initial temperatures (0 °C, 21 °C, 48 °C, and 82 °C) and in a cold, carbonated beverage (0 °C). The liquid height was fixed at 2/3 of the paper straw’s height. The longevity test exposed samples for different time lengths (0.5, 1.0, 2.0, 3.0, 4.0, and 6.0 h). For each time length, the entire sample was immediately weighed, and an axial and compression test was performed with the wet samples using the bottom part of the straw.

The paper straw tensile strength was measured based on the TAPPI T494 om-01 standard (2006) using a horizontal tensile tester (TMI 84-56; Testing Machines, Inc., New Castle, DE, USA) with an initial gap of 30 mm. The plastic straw tensile strength was measured based on ASTM D882-12 (2012) with a tensile testing machine (4443; Instron, Norwood, MA, USA) with an initial gap of 25 mm.

The compressive strength for both plastic and paper samples was measured based on ASTM D695-15 (2018) and ASTM D2412-11 (2018) using a tensile testing machine (4443; Instron, Norwood, MA, USA). The axial and radial configuration for compression was tested. A compression speed test of 10 mm/min was used for the axial configuration using samples with a length/diameter ratio of 2. A compression speed test of 1 mm/min was used for the radial configuration with a length/diameter ratio greater than 8.

A surface electro-optics (SEO) contact angle analyzer (Phoenix 300; Surface Electro-Optics Co., Ltd., Suwon City, Gyeonggi-do, Korea) was used to determine the contact angle and the surface tendency of the paper straws to absorb liquid. The angle was measured 10 s after the drop touched the surface. To control the formation speed of the drop, the software equipment defined the fast speed at 47 and the slow speed at 32. The drop that formed on the samples took 10 s for each trial before touching the surface. An industrial needle with a gauge of 27 was used for all tests.

Thirty paper straws of each brand were soaked in 1 L of water for 24 h to determine whether materials leached from the paper straws. The water was then analyzed with a portable turbidity meter (2020wi; LaMotte, Chestertown, MD, USA). Turbidity is the measurement of water cloudiness caused by particles suspended in the liquid (World Health Organization 2011), although each measurement method uses different units. For example, the nephelometric turbidity unit (NTU) is used by the Environmental Protection Agency (EPA) standard (Fondriest Environmental, Inc. 2014) and the formazin nephelometric unit (FNU) is used by the ISO standard (Hach 2019). However, these units can be considered equivalent, according to ASTM D6855-17 (2017).

RESULTS AND DISCUSSION

The length, external diameter, and internal diameter were measured for all straws tested. The thickness shown in Table 2 was calculated. The caliper was measured using a Vernier (Traceable Digital Calipers, Fischer Scientific, Hampton, NH, USA). The results shown in Table 3 were calculated based on these measurements. Despite the different dimensions of the plastic straw samples, the thickness of each sample was similar. The dimensions of the paper straw samples were similar as well, but the apparent density changed between the brands and had a relative difference of approximately 12%.

Table 2. Dimensions and Calculated Properties of Plastic and Paper Straws

Table 3. Calculated Properties of Plastic and Paper Straws

Fiber Quality Analyzer (FQA) Analysis

The FQA results are shown in Table 4. The fiber length and the coarseness indicated that all paper straws were made mainly of hardwood fibers. Hardwood fibers are approximately 1 mm in length with a coarseness of 0.08 mg/m (Smook 2002).

Contact Angle

The contact angle test reflects the relative hydrophobicity of the straws, as shown in Table 5. Generally, a contact angle with water larger than 90° forms with hydrophobic surfaces, and less than 90° for hydrophilic surfaces (Zhao and Jiang 2018). The contact angle for the plastic samples was between 80° and 98°. For all paper straws, the tested surface was considered hydrophobic because the angles were between 102° and 125°. The surface of the paper straws was more hydrophobic than that of the plastic straws; this is an indication of surface treatment made on the paper. The untreated paper will have a lower contact angle, and will absorb the liquid, additionally reducing the contact angle noticeably over time (Moutinho et al. 2007; Tyagi et al. 2019). On the other hand, the plastic straws are not expected to take up any significant amount of water, as the paper straws might, and the contact angle considered constant with time.

Table 4. Paper Straw Fiber Quality Analysis (FQA)

Note: L n = Arithmetic average of fiber length and L w = weighted average fiber length

Table 5. Contact Angle for Paper and Plastic Straws (10 s)

Dry Tensile Strength

The tensile strength was measured for the plastic and paper straws, Tables 6 and 7. Because of the inherent difference between these two materials, a fair comparison between the tensile properties was established using the specific strength and calculated by dividing the tensile strength by the density of the respective material. In this manner, the paper straws had a similar value between them, but the value changed considerably for the plastic straws. However, the paper straws had a higher specific strength with the exception of one of the plastic samples.

Fold Endurance

The fold endurance test determined the capacity of the straw to withstand repeated bending. The plastic straws offered a considerably higher resistance to this stress (Table 6). However, the paper straws were strong enough to resist typical usage and were unbroken after being bent multiple times (Table 7).

Table 6. Mechanical Measurements for the Plastic Straws. Tested under standard TAPPI conditions (23 °C and 50% relative humidity (RH))

Table 7. Mechanical Measurements for the Paper Straws. Tested under standard TAPPI conditions (23 °C and 50% relative humidity (RH))

Figure 1 shows the plots of the strongest plastic and paper straws during the tensile test and displays the expected behavior of these types of polymeric materials.

Fig. 1. Average tensile strength curves for paper and plastic straws; strongest plastic (plastic1) and paper1, paper2, and paper3. Enlargement of range to 0.1 mm/mm.

Overall, the plastic tended to be stronger than the paper. The force needed to break the paper samples was 60% of the force needed to break the plastic straw, and the plastic straws could stretch roughly ten times or more before failure. In addition, the paper straws failed at 3.6% to 4.1% of strain, and the paper was stiffer than the plastic.

Figure 1 shows a typical tensile curve for polymers (green trend), with a Hookean or elastic region with a linear response (Young’s modulus) of strain and increasing stress. The tensile yield strength was the first point where the linear trend ceased, and the plastic deformation started. The ultimate stress was the reported tensile strength and is the maximum load the material can stand before it breaks, divided by the initial transversal area.

Axial Compression

Table 8 shows the compressive strength for the plastic and paper straws for the axial configuration. The Paper3 straws achieved the highest compressive strength of the paper straws, but when compared with plastic, the paper could only withstand half of the force of the strongest plastic straw.

Table 8. Dry Axial Compressive Strength for Plastic and Paper

Figure 2 shows the strongest of the plastic straws in contrast with the three brands of paper straws. The plastic cylindrical structure presented a narrower peak and the highest compression stress before it collapsed. In contrast, the paper showed a broader curve and reached the maximum load at a higher strain before it failed.

Fig. 2. Average compressive strength curves in the axial direction for plastic straws and the three brands of paper straws

Radial Compression

The results of the radial configuration compressive strength are shown in Table 9. The paper straws exhibited more strength and a higher modulus than the plastic straws. The plastic deformed more easily, with more obvious elastic (reversible deformation) behavior. People often enjoy this property, as they sometimes like to repeatedly bite the straw and have it come back to its original state. This reversible deformation is not as likely with paper straws.

Table 9. Dry Radial Compressive Strength for Plastic and Paper Straws

Paper2 (Brown) displayed the lowest strengths for both the axial and radial configurations. The axial configuration had a more considerable load tolerance than the radial configuration due to a geometrical configuration that allows an even distribution of the stress through the entire structure.

Figure 3 shows the radial compression curves of the plastic and paper straws. The transition between the elastic and plastic regions was not easy to distinguish in the plastic curve but was more easily shown in the paper curve. This means that the plastic acted as an elastic material without the plastic region for the strain tested. In addition, the paper could not recover the initial geometry of the material after the test, as did the plastic samples.

Fig. 3. Average compressive strength curves in the radial direction for plastic straws and the three brands of paper straws

Weight Gain for Different Liquids

The first part of the longevity test was to measure how much liquid the straws in the test conditions retained as a function of time. Figure 4 shows the weight gain of the straws due to water absorption versus time at room temperature. The weight gain increased at a high rate for the first 20 min, and then at a slower rate after that. Plastic straws showed negligible weight gain in all cases.

Fig. 4. Weight gain for paper straws in water at 21 °C in 5 min intervals

Fig. 5. Weight gained for (a) Paper1 (White), (b) Paper2 (Brown), and (c) Paper3 (Color) in three different beverages with an initial temperature of 0 °C

Figure 5 shows the weight gain as a percentage for Paper1 (White) (Fig. 5a), Paper2 (Brown) (Fig. 5b), and Paper3 (Color) (Fig. 5c) for some common beverages. This test was performed using the same initial temperature and liquid height in three different but common cold beverages: water, a carbonated beverage (Coke), and sweet tea. The most noticeable difference was between paper straw types rather than liquids. The Paper1 (White) straws gained up to 75% of their weight after four h of testing, while the other two brands only gained approximately 30% each. These results suggest that the brand of Paper1 (White) lacked the coating or protective material or had less internal sizing than did the other paper straws.

Weight Gain for Different Temperatures

Similarly, the three brands of paper straws were tested using water at three different temperatures ( i.e. , 0 °C, 21 °C, and 48 °C). Paper1 (White) retained more liquid than the other paper straws. For Paper2 and Paper3 straws, the weight gain was higher for the higher liquid temperature, as expected. However, for Paper1 the opposite was true (Figure 6).

Fig. 6. Weight gained for (a) Paper1 (White), (b) Paper2 (Brown), and (c) Paper3 (Color) in water at three different initial temperatures

Effects of the Paper Straw and Liquid Interactions

A concern for using paper straws is how the appearance of the liquid and the straws are affected by the interaction between them. The appearance of the paper straws after 30 min and 6 h after being in contact with Coke is shown in Table 10. It is observed that the paper straws all showed a distinct darkening due to the absorption of the Coke.

Table 10. Paper Straw Appearance After Longevity Test

To investigate whether the straws released any material/particles during the contact with the liquids, the turbidity of the water was measured after 6 and 24 h of the straws being in contact with the water. The appearance of the straws after 24 h in water is also shown in Table 10. The results indicated that the paper straws acquired the color of the liquid, but the straws did not visually change the appearance of the liquid and did not release any solids into the liquid, even under periods considerably larger than the average for these single-use disposable materials.

Material Transfer from Straw to Liquid Measured by Turbidity

The turbidity values obtained from the paper straws being in contact with water for 24 h are shown in Table 11. The liquid was completely clear to the human eye with an average value of 0.56 FNU (formazin nephelometric unit).

Table 11. Turbidity Measurement after 24 h of Direct Contact between Water and Paper Straws

Compression of Paper Straws Exposed to Liquid

Fig. 7. Axial compressive strength vs. time for straws immersed in: (a) Coke at an initial temperature of 0 °C (temperature remained at 0 °C for 3 h, and after 6 h, the temperature reached 15 °C); (b) water at an initial temperature of 0 °C (temperature remained at 0 °C for 3 h, and after 6 h, the temperature reached 15 °C); (c) water at an initial temperature of 21 °C; (d) water at an initial temperature of 48 °C; and (e) water at an initial temperature of 82 °C

To be seen by the naked eye, the value must be at least 4 FNU (World Health Organization 2011), 55 FNU for a cloudy suspension, and 515 FNU for an opaque suspension (Fondriest Environmental, Inc. 2014). The values indicated that no relevant amount of solid migrated in the liquid. Considering that drinking water needs to have a value under 10 FNU to be acceptable, the paper straws did not noticeably contaminate the liquids after 24 h of direct contact (Minnesota Pollution Control Agency 2008; Muthuraman and Sasikala 2014).

Axial compression

In this section, the second part of the longevity test is discussed. The compressive tests of the paper straws in wet conditions as a function of time, with an initial liquid temperature and a fixed liquid height, was conducted. The axial and radial configurations were evaluated.

Figure 7a shows the compressive strength of the paper straws relative to the dry condition (point zero) as a function of time. The strength decreases by about 80% within the first 30 min and then retained that level throughout the rest of the test. The reduction of force was approximately 90% in some cases. The Paper3 (Color) straws remained as the brand with the highest compressive strength at every condition, in all liquids tested and at all temperatures. As shown in Figs. 7a and 7b, when the Coke and water were at the same initial temperature (0 °C), there was no relevant difference in compressive strength between the two beverages. As shown in Figs. 7b through 7e, initial temperature increases reduced the compressive strength of the paper straws even further. Several samples completely lost their structural integrity in the water at 82 °C, making the compression test not possible for these samples.

Radial compression

The longevity tests of the paper straw compressive strength in the axial direction of the straws are discussed in this section. The results for water at 0 °C and 21 °C, and Coke at 0 °C after two h in direct contact with the liquid are shown in Tables 12 to 14 for the paper straws.

Table 12. Radial Compression Strength for Paper1 (White) Straws out of the box* and after 2 h immersed in liquid

*Out of the box refers to the results of Table 9, the compressive test of the straws before contact with any liquid

The Paper3 (Color) straws remained the strongest in terms of the load they could sustain. Similar to the axial configuration, the paper straws lost 80% to 90% of their compressive strength after exposure to the liquids for 30 min.

Table 13. Radial Compression Strength for Paper2 (Brown) Straws out of the box* and after 2 h immersed in liquid

Table 14. Radial Compression Strength for Paper3 (Color) Straws out of the box* and after 2 h immersed in liquid

The longevity test was also performed with water at different initial temperatures, as shown in Fig. 8.

The results show how the compressive strength was reduced by 80% to 85% after 30 min and remained in this range during the remainder of the test. Like the axial configuration, a higher temperature negatively affected the radial compressive strength and further reduced the results to close to 90% of the dry value.

Fig. 8. Radial compressive strength vs. time for straws immersed in water at (a) an initial temperature of 48 °C and (b) an initial temperature of 82 °C

CONCLUSIONS

- The paper straws were made mainly of hardwood fibers and had been treated to increase their hydrophobicity. Their surfaces formed initial contact angles with water in the range of 100° to 125°, indicative of hard sized paper surfaces.

- The paper straws experienced weight gain almost immediately after exposure to liquids and gained weights of 30% to 50% within 60 min.

- The plastic straws were generally stronger than the paper straws in the dry state and did not gain weight when immersed in fluids. Plastic straws did not display any decreases in mechanical properties upon immersion in liquids

- Paper straws displayed higher compressive strength in the radial configuration under dry conditions than the plastic straws; however, the plastic straws returned to the original shape after release of the force, and the paper straws did not.

- The type of fluid did not have a noticeable impact on the weight gain or wet strength of the paper straws.

- An increase in the liquid temperature increased the weight gained for the paper straws and reduced the wet strength.

- The paper straws did not release appreciable particle solids into the liquids as evidenced by liquid turbidity measurements before and after exposure to the paper straws.

- None of the paper straws evaluated had considerable stability after 30 min in liquids, losing 80% to 90% of their strength within 30 min of exposure to liquid.

- Tracking of the time-dependent weight gain and compressive strength of paper straws under immersion of liquids was an insightful way to evaluate paper straw product performance.

ACKNOWLEDGMENTS

The authors are thankful to Dr. Ved Naithani for assisting in conducting the FQA testing.

REFERENCES CITED

Aardvark. (2019). “AArdvark Straws,” <https://www.aardvarkstraws.com/ecoflex-paper-straws>.

Andrady, A. L. (2011). “Microplastics in the marine environment,” Marine Pollution Bulletin 62(8), 1596-1605. DOI: 10.1016/j.marpolbul.2011.05.030

ASTM D695-15 (2015). “Standard test method for compressive properties of rigid plastics,” ASTM International, West Conshohocken, PA.

ASTM D882-12 (2012). “Standard test method for tensile properties of thin plastic sheeting,” ASTM International, West Conshohocken, PA.

ASTM D2412-11 (2018). “Standard test method for determination of external loading characteristics of plastic,” ASTM International, West Conshohocken, PA.

ASTM D6855-17 (2017). “Standard test method for determination of turbidity below 5 NTU in static mode,” ASTM International, West Conshohocken, PA.

British Broadcasting Corporation (BBC) (2018). “Most paper straws are made in Asia but now UK firms are starting to produce them again,” BBC , (https://www.bbc.com/news/av/business-45740772/most-paper-straws-are-made-in-asia-but-now-uk-firms-are-starting-to-produce-them-again), Accessed 3 Feb 2019.

Brueck, H. (2018). “The real reason why so many cities and businesses are banning plastic straws has nothing to do with straws at all,” Business Insider , (https://www.businessinsider.com/plastic-straw-ban-why-are-there-so-many-2018-7), Accessed 3 Feb 2019.

Chokshi, N. (2018). “How a 9-year-old boy’s statistic shaped a debate on straws,” The New York Times , (https://www.nytimes.com/2018/07/19/business/plastic-straws-ban-fact-check-nyt.html), Accessed 4 Feb 2019.

Danovich, T. (2018). “Why people with disabilities want bans on plastic straws to be more flexible,” <https://www.npr.org/sections/thesalt/2018/07/11/627773979/why-people-with-disabilities-want-bans-on-plastic-straws-to-be-more-flexible>.

Eagle, L., Hamann, M., and Low, D. R. (2016). “The role of social marketing, marine turtles and sustainable tourism in reducing plastic pollution,” Marine Pollution Bulletin 107(1), 324-332. DOI: 10.1016/j.marpolbul.2016.03.040

Fondriest Environmental, Inc. (2014). “Measuring turbidity, TSS, and water clarity,” Fondriest Environmental Learning Center , (https://www.fondriest.com/environmental-measurements/measurements/measuring-water-quality/turbidity-sensors-meters-and-methods/), Accessed 4 Feb 2019.

Geyer, R., Jambeck, J. R., and Law, K. L. (2017). “Production, use, and fate of all plastics ever made,” Science Advances 3(7), 25-29. DOI: 10.1126/sciadv.1700782

Hach (2019). “What is the difference between the turbidity units NTU, FNU, FTU, and FAU? What is a JTU?,” (https://support.hach.com/app/answers/answer_view/a_id/1000336/~/what-is-the-difference-between-the-turbidity-units-ntu%2C-fnu%2C-ftu%2C-and-fau%3F-what>), Accessed 4 Feb 2019.

Haetrakul, T., Munanansup, S., Assawawongkasem, N., and Chansue, N. (2009). “A case report: Stomach foreign object in whaleshark ( Rhincodon typus ) stranded in Thailand,” in: Proceedings of the 4th International Symposium on SEASTAR 2000 and Asian Bio-logging Science (The 8th SEASTAR 2000 workshop) , Phuket, Thailand, pp. 83-85.

Minnesota Pollution Control Agency (2008). Turbidity: Description, Impact on Water Quality, Sources, Measures – A General Overview , Minnesota Pollution Control Agency, St. Paul, MN, USA.

Minter, A. (2018). “Plastic straws aren’t the problem,” Bloomberg , (https://www.bloomberg.com/opinion/articles/2018-06-07/plastic-straws-aren-t-the-problem), Accessed 8 Feb 2019.

Moutinho, I., Figueiredo, M., and Ferreira, P. (2007). “Evaluating the surface energy of laboratory-made paper sheets by contact angle measurements,” Tappi Journal , (6), 26-32.

Muthuraman, G., and Sasikala, S. (2014). “Removal of turbidity from drinking water using natural coagulants,” Journal of Industrial and Engineering Chemistry 20(4), 1727-1731. DOI: 10.1016/j.jiec.2013.08.023

Ocean Conservancy (2017). “Building a clean swell,” Oceanconservancy.org , (https://oceanconservancy.org/wp-content/uploads/2018/07/Building-A-Clean-Swell.pdf), Accessed 12 Feb 2019.

Purtill, C. (2018). “Ban plastic straws. Just don’t use paper ones, because they’re awful,” Quartzy , (https://qz.com/quartzy/1324163/ban-plastic-straws-just-dont-use-paper-ones/), Accessed 20 Feb 2019.

Shah, A. A., Hasan, F., Hameed, A., and Ahmed, S. (2008). “Biological degradation of plastics: A comprehensive review,” Biotechnology Advances 26(3), 246-265. DOI: 10.1016/j.biotechadv.2007.12.005

Simmonds, M. P. (2012). “Cetaceans and marine debris: The great unknown,” Journal of Marine Biology 2012, Article ID 684279. DOI: 10.1155/2012/684279

Smith, E. (2017). “A brief history of the modern-day straw, the world’s most wasteful commodity,” Atlas Obscura , (https://www.atlasobscura.com/articles/straws-history), Accessed 20 Feb 2019.

Smook, G. A. (2002). Handbook for Pulp and Paper Technologists , Angus Wilde Publications Inc., Vancouver, Canada.

Sorensen, E., and Reinke, J. (2018). “Inside the only U.S. paper straw manufacturer,” Industrial Equipment News , (https://www.ien.com/operations/video/21017274/inside-the-only-us-paper-straw-manufacturer), Accessed 25 Feb 2019.

Starbucks Stories (2018). “Starbucks and closed loop partners to develop recyclable, compostable cup solution,” Starbucks Stories , (https://stories.starbucks.com/stories/2018/starbucks-and-closed-loop-to-develop-recyclable-compostable-cup-solution/), Accessed 25 Feb 2019.

TAPPI T494 om-01 (2006). “Tensile properties of paper and paperboard (using constant rate of elongation apparatus),” TAPPI Press, Atlanta, GA.

TAPPI T511 om-02 (2008). “Folding endurance of paper (MIT tester),” TAPPI Press, Atlanta, GA.

Szymkowiak, J. (2018). “Guest Blog: Action on plastics shouldn’t make life suck for disabled people,” <https://www.greenpeace.org/canada/en/story/735/guest-blog-action-on-plastics-shouldnt-make-life-suck-for-disabled-people/>.

The Guardian (2018). “Starbucks to ditch plastic straws globally by 2020 to help environment,” The Guardian , (https://www.theguardian.com/business/2018/jul/09/starbucks-eliminate-plastic-straws-globally-2020), Accessed 5 March 2019.

Tyagi, P., Lucia, L. A., Hubbe, M. A., and Pal, L. (2019). “Nanocellulose-based multilayer barrier coatings for gas, oil, and grease resistance,” Carbohydrate Polymers , 206(15), 281–288. DOI: 10.1016/j.carbpol.2018.10.114.

Thompson, D. (2011). “The amazing history and the strange invention of the bendy straw,” The Atlantic , (https://www.theatlantic.com/business/archive/2011/11/the-amazing-history-and-the-strange-invention-of-the-bendy-straw/248923/), Accessed 10 Feb 2019.

TAPPI T271 om-07 (2012). “Fiber length of pulp and paper by automated optical analyzer using polarized light,” TAPPI Press, Atlanta, GA.

TAPPI T402 sp-08 (2013). “Standard conditioning and testing atmospheres for paper, board, pulp, handhsheets, and related products,” TAPPI Press, Atlanta, GA.

United Nations Environment Programme (UNEP) (2018). Single-use Plastics: A Roadmap for Sustainability , Economy Division of UNEP, Tsurumi-ku, Osaka, Japan.

Wootson, C. R. (2018). “Seattle becomes first major U.S. city to ban straws,” The Washington Post , (https://www.washingtonpost.com/news/post-nation/wp/2018/07/01/seattle-becomes-first-major-u-s-city-to-ban-straws/?noredirect=on&utm_term=.dc9444785166), Accessed 10 March 2019.

World Health Organization (WHO) (2011). “Acceptability aspects: Taste, odour and appearance,” Guidelines for Drinking-water Quality 38(3), 219-230.

Zhao, T., and Jiang, L. (2018). “Contact angle measurement of natural materials,” Colloids and Surfaces B: Biointerfaces 161, 324-330. DOI: 10.1016/j.colsurfb.2017.10.056

Article submitted: April 14, 2019; Peer review completed: July 13, 2019; Revised version received: August 23, 2019; Accepted: August 24, 2019; Published: September 4, 2019.

DOI: 10.15376/biores.14.4.8345-8363

Advertisement

Bio-based alternatives to plastic drinking straws: are they more environmentally benign and consumer preferred?

- Original Article

- Open access

- Published: 27 July 2023

- Volume 2 , article number 28 , ( 2023 )

Cite this article

You have full access to this open access article

- Yinglin Liang 1 ,

- Jiazhou He 1 ,

- Min Zhuang 2 ,

- Fayuan Chen 3 ,

- Kui Yang 1 &

- Jinxing Ma ORCID: orcid.org/0000-0002-5087-3972 1

7880 Accesses

7 Citations

3 Altmetric

Explore all metrics

The global production of nondegradable catering straws has skyrocketed due to their versatile properties, which results in significant CO 2 emissions and pollution of the ecological system. While paper and polylactic acid straws have gained increasing popularity in the beverage industry, there needs to be more investigation of the vital product properties determining their hedonic differences. This study systematically compared the properties of paper, polylactic acid and plastic straws, and their impacts on the consumer experience and willingness. Results showed that the open structure of paper straws prompted water penetration and absorption, reaching a water absorption of 30% after 10-min wetting, which might affect the taste of the drink. In contrast, the compact polymer matrices of polylactic acid straws prevented mass exchange in their use for drinking but retarded product biodegradation under natural conditions. Results of consumer testing showed that while the participants had a comparable liking of paper and polylactic acid straws to insert into a drink (i.e., 4.16 and 4.47 out of 5, respectively), the intrinsic difference was covered up by the open-ended capping for beverages. For the “fully sealed on top” dataset, paper straws dropped to 3.46, while that for polylactic acid straws remained at 4.70. Furthermore, a biodegradable straw easily inserted into a drink without fracture may positively prompt merchants’ revenue. This study is expected to pave the way for the advancement and widespread use of bio-based products.

Graphical Abstract

30% water absorption in biodegradable paper straws affects the taste of drinks.

Preferable polylactic acid straws had < 0.3% mass loss after 30 days in natural soil.

Open-ended design of beverages covers up liking differences between straws.

Similar content being viewed by others

Bio-straw or not? Determinants of consumption intention under the plastic straw ban

Extending Product Categories as a Potential for the Development of Paper Production Enterprises: A Case Study

Exploring the effects of structure and melting on sweetness in additively manufactured chocolate

Avoid common mistakes on your manuscript.

1 Introduction

Over the past few decades, the production of nondegradable plastics has skyrocketed due to their versatile properties, increasing more than 20-fold, reaching 360 million metric tons annually (PlasticsEurope. 1950 ; Andrady 2011 ). Most plastic products continue to be made from fossil fuels, the overexploitation and consumption of which have driven a global climate crisis (Heede 2014 ). Plastics contribute to anthropogenic CO 2 emission throughout their cradle-to-grave life cycle (G. C 2022 ; Fahim et al. 2019 ), and the production of plastics is projected to account for about 15% of the total greenhouse gas emissions by 2050 (Foundation 2016 ). In addition, the disposal of plastics (e.g., via landfill or dumping into the sea) has negatively impacted ecological systems (Baulch and Perry 2014 ; Jimenez et al. 2015 ; Drever et al. 2018 ). More recent evidence shows that, subject to abiotic factors such as UV radiation and physical stress for a long time, single-use plastics would be fragmented into smaller particles, termed microplastics (Urbanek et al. 2018 ). Microplastics have attracted concerns worldwide due to their more adverse effects and wider distribution than other materials (Liu et al. 2020 ; Lusher et al. 2015 ; Wang et al. 2017 ; Zhang, et al. 2020 ). These hazardous materials can eventually enter the human body through the biological chain because of their refractory nature and tiny size (Ragusa, et al. 2021 ; Schwabl et al. 2019 ). Researchers have hypothesized that the health impacts may include cell damage, inflammation, and immune reactions (Jin, et al. 2021 ).

In the beverage industry, plastic straws have recently gained notoriety due to their emblematic nature as a source of plastic waste. For instance, it is estimated that the number of daily-used plastic straws in the United States alone reaches 170 − 500 million (Chokshi 2018 ). As a result, many countries have issued bans and regulations to mitigate the adverse effects of single-use plastics (Viera et al. 2020 ). While sharing plastic tableware has been indicated to provide a potential solution that addresses waste dilemmas and environmental footprints (Zhou, et al. 2020 ), reusable straws in public places are not always hygienic, especially during the COVID-19 pandemic. To this end, developing and deploying sustainable alternatives to plastic straws in catering is essential. Paper and bioplastic straws have therefore gained increasing popularity in recent years.

Paper straws are made from hardwood fibers widely distributed in nature, which feature the merits of low cost and complete biodegradability. Natural cellulose can be used in two ways for straws: natural fibers used for pulp products and extracted cellulose dosed as a guest filler (Ma et al. 2022 ). Polylactic acid (PLA) straws, a biobased product, are produced from monomers that are made from corn, beet sugar, and cane sugar in the process of either ring-opening polymerization of lactides or condensation polymerization of the lactic acid monomers (Auras et al. 2011 ; Rudnik 2019 ). Currently, there is very little research on the strengths and weaknesses of these substitutes in catering. Regarding the raw materials and production process, one would expect paper straws to be cheaper ($1800–2500/ton) (Raghavan 2019 ); however, manufacturers may increase the wall thickness in pursuit of better mechanical properties, thus weakening the price advantage of pulp products. Moreover, paper straws have been criticized for their unpleasant experience since soggy paper straws quickly lose their mechanical integrity, and some straws may even change the drink’s taste (Purtill 2018 ). Although there has been investigation on the sensory category of straws (Lin et al. 2013 ; Akiyama et al. 2012 ), few studies were conducted to evaluate the key factors determining the hedonic differences between plastic straw replacements. A comprehensive understanding of the correlation among the chemical characteristics of “biodegradable” straws, their performance, and user feedback is crucial to developing excellent alternatives to traditional fossil fuel-based straws and achieving sustainable development goals. However, relevant studies are still needed to make it available.

Therefore, this study systematically investigates the property, end-of-life impacts, and consumer experience of paper and PLA straws compared with that of plastic ones. We characterized the chemical composition, morphology, dynamic mechanical strength at varying temperatures, and leaching properties of the straw specimens. Consumer testing and questionnaire survey were carried out to evaluate how the experience, such as mouthfeel and ease of inserting into a drink, was correlated to the straw properties and then influenced the willingness to purchase. This study aims to provide crucial information for the widespread use of alternative biodegradable beverage products.

2 Materials and methods

2.1 reagents and straws.

In this study, all chemicals were purchased from Sigma Aldrich unless stated elsewhere. All solutions were prepared in Milli-Q (MQ) water with 18 MΩ cm resistivity. Commercial straw samples made of polylactic acid (PLA), paper pulp, and polypropylene (PP) that are commonly used in the beverage industry were compared to assess the differences between “biodegradable” and traditional plastic straws. Three brands of PLA straws, three brands of paper straws, and one polypropylene (PP) straw were purchased from different vendors and termed PLA-1, PLA-2, PLA-3, Pulp-1, Pulp-2, Pulp-3, and PP, respectively. Detailed information on the straw samples is summarised in Table 1 .

2.2 Characterization

The characteristic functional groups of the straw specimens were determined by Fourier-transform infrared (FTIR) spectroscopy (IRTracer-100, Shimadzu) in attenuated total reflectance (ATR) mode. The scan resolution was 4 cm −1 from 400 to 4000 cm −1 , with each sample scanned 32 times. The morphology and texture were assessed on a scanning electron microscope (SEM), TESCAN MIRA LMS, Czech, under an accelerating voltage of 10 keV in a vacuum. The gold spray was conducted prior to SEM imaging. The inner surface hydrophobicity of the materials was characterized by the contact angle of MQ water on the straw employing an Attension Theta Lite, TL 101 Optical tensiometer (Biolin Scientific).

Two immersion time sets of 10 and 30 min (termed t 1 and t 2 , respectively) were used for the water absorption tests. Briefly, the straw samples were dried in an oven at 105 ºC for 24 h, then cooled to room temperature and weighed to obtain a starting value of m 0 . The samples were then immersed in 100 mL of MQ water. Following predetermined time intervals of t 1 and t 2 , the corresponding samples were withdrawn and residual surface waster was gently wiped off before mass determination (that resulted in m 1 and m 2 ). The change of the conductivity of the MQ water (i.e., ∆ ρ = ρ t − ρ 0 ≈ ρ t ) was determined by a Myron L® conductivity meter to evaluate the ion leaching from different samples. The relative water absorption rate (RA) of each straw was calculated as Eq. 1 :

where i = 1 or 2 corresponding to t 1 = 10 min or t 2 = 30 min. Because the paper straws exhibited significant water absorption and ion leaching, the dissolved heavy metals (Hg, Cr, Cu, Zn, Cd, and Pb) and conventional metals (Na, K, Ca, and Mg), if any in the extractant (MQ water), were quantified on an inductively coupled plasma source mass spectrometer (ICP-MS, Thermo, ICAP RQ).

Dynamic mechanical analysis (DMA) was used in this study to analyze the thermal dynamic mechanical properties of said straw samples (Ebnesajjad 2014 ; Panwar 2017 ). DMA specimens (12 × 10 mm) were tested with an amplitude of 20 μm, a frequency of 1 Hz, and a scanning temperature range from room temperature to 100 °C on DMA + 300, Metravib. The experiments mentioned above were all repeated at least three times.

2.3 Biodegradability assay

Natural soil tests of the PLA, pulp and PP straws were conducted to explore the degree and rate of aerobic/anaerobic biodegradation of plastic materials in a controlled environment (Kim et al. 2006 ). The soil selected in the burial experiment was humus soil formed by long-term decay and fermentation of deciduous leaves. A controlled-environment chamber ( i.e. , a stainless-steel box with a size of 130 mm ( L ) × 68 mm ( W ) × 70 mm ( H )) capable of maintaining near-neutral pH, a temperature of 25 ± 2 °C and water content of 50–60% was used (Fig. S 1 a). The mass weights ( M 0 ) of the pristine samples were recorded before the soil burial tests. The pieces were then buried at about 20 mm from the soil surface, and the appropriate amount of water was added to maintain the water content (Fig. S 1 b). Finally, covering soil was applied to the top without sealing. Two experimental groups ( A 15 and A 30 ) were set up according to the duration of landfill time ( i.e. , 15 and 30 days). Thereafter, the samples were withdrawn and gently cleaned with MQ water. The residue mass was measured ( M 15 and M 30 ) to compare the biodegradability in soil. The mass loss rate was calculated according to Eq. 2 :

where j = 1 or 2 corresponding to t 1 = 15 days or t 2 = 30 days.

2.4 Survey and consumer testing

To comprehensively assess the consumer experience of the straws tested, three types of beverages (fast-moving consumer goods (FMCG) coffee, milk tea, and fruit tea) were purchased for a survey and consumer testing. The temperatures of 500 mL beverages were set at low (0 − 5 °C), room (25 ± 5 °C), and medium (40 ± 5 °C) values. Some of the beverages (e.g., milk tea) contained large-size toppings such as tapioca balls (particle size 5 − 8 mm), while the others contained small-size, soft (e.g., jelly), or no toppings. Drinks with a PLA, paper or PP straw were randomly assigned to the study population in the survey. While participants decided how long to finish their drinks, during which straws were soaked, according to their dietary habits, most tests (~ 80%) were finalized within 60 min with the participants informed to complete the questionnaire (Table 2 ).

In this consumer test, nineteen questions were included in the questionnaire. All straw samples were labeled with 1 − 7 numbers corresponding to Pulp-1, Pulp-2, Pulp-3, PLA-1, PLA-2, PLA-3, and PP, respectively. The correlation information was blind to the participants. The panelists were asked to evaluate their experience of inserting the straw and their liking of the straw mouthfeel (Q10 and Q12 in Table 2 ), all on 5-point hedonic scales (Jonsson et al. 2021 ). “5” indicated the best consumer experience, while “1” was the worst experience. Sixty-eight participants aged 18 − 37 were included in the survey. The questionnaire was distributed to the participants via the online software, Questionnaire Star ( https://www.wjx.cn/ ), and the anonymous survey results were collected from this platform. A demo of the online interface is shown in SI Section S 1 , with the complete data set available upon email request. A t -test was used to compare the means of two groups. Statistical significance was assumed at p < 0.05 (Ma et al. 2018 ).

2.5 Ethics declarations

All methods were carried out in accordance with relevant guidelines and regulations, and all experimental protocols were approved by the ethics committee at the Guangdong University of Technology (Reference number: GDUTXS2022102). All participants gave informed consent via the statement “I am aware that my responses are confidential, and I agree to participate in this survey.” They could withdraw from the survey at any time without giving a reason. The products tested were safe for consumption.

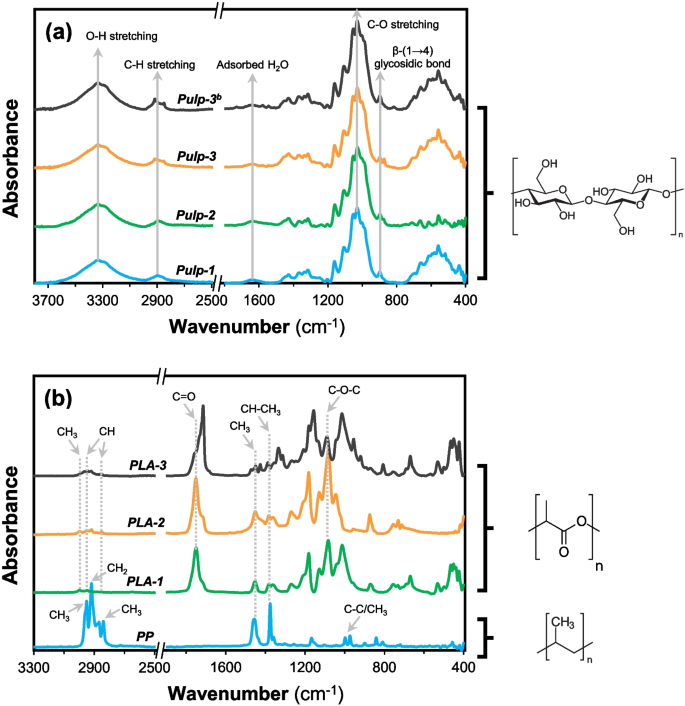

3.1 Composition and morphology characterization of straws

The three paper straws demonstrated similar infrared absorption spectral characteristics (Fig. 1 a). Notably, the peak located at 899.5 cm −1 relates to the presence of β-(1 → 4) cellulose glycosidic bond (Oh et al. 2005 ; Pandey and Pitman 2003 ; Xu et al. 2013 ), while the board band between 1200 − 1100 cm −1 should be ascribed to the C-O bond stretching vibration (Makarem et al. 2019 ; Onyianta et al. 2018 ). In addition, the FTIR peaks at ~ 2900 and 3000 − 3700 cm −1 respectively indicated the absorption caused by the asymmetric stretching of -CH 2 with -CH (Makarem et al. 2019 ; Lun et al. 1835 ) and the structure of cellulose with hydroxyl groups and intra-/intermolecular hydrogen bonds (Makarem et al. 2019 ; Onyianta et al. 2018 ; Hinterstoisser and Salmén 1999 ). These results confirmed that plant fibers should be the host material of the paper straws used in this study (Onyianta et al. 2018 ; Lun et al. 1835 ). Furthermore, we compared the FTIR spectral characteristics of the inner and outer wall surfaces of Pulp-3 because there was a significant difference in their appearances (i.e., a white inner wall vs. a brown outer wall, as shown in Table 1 ); however, their FTIR patterns were almost identical (Fig. 1 a), indicating that the matrix of the paper straw was largely homogenous.

Chemical composition analysis of straw samples. Fourier-transform infrared (FTIR) spectra in attenuated total reflectance (ATR) mode of a pulp straw samples and b PLA and PP products. The acronyms of straws refer to Table 1 . Pulp-3 b represents the outer wall surface

In comparison, there were apparent differences in the FTIR spectral peak intensities and wavenumbers among the PLA samples (Fig. 1 b), probably due to the different production processes (Auras et al. 2011 ; Rudnik 2019 ) and various types and dosages of guest materials added. Nevertheless, characteristic peaks of polylactic acid units were noted for all PLA straw samples, including the stretching vibrations of C–O–C, C = O, -CH 3 , and -CH, respectively, at 1130, 1747, 1452, and 2947 cm −1 (Yuniarto n.d.; He and Inoue 2000 ; Leroy et al. 2017 ). In addition, the characteristic absorption peaks of polypropylene (Fig. 1 b) related to the asymmetric stretching vibration of -CH 3 at near 2952 cm −1 and -CH 2 - symmetric bending and asymmetric stretching at 1455, 2838, and 2917 cm −1 (Aravinthan et al. 2019 ). Based on the composition analysis results, we can conclude that the straw samples used in this study represented the paper, PLA, and PP straws commonly provided in the beverage and FMCG industries.

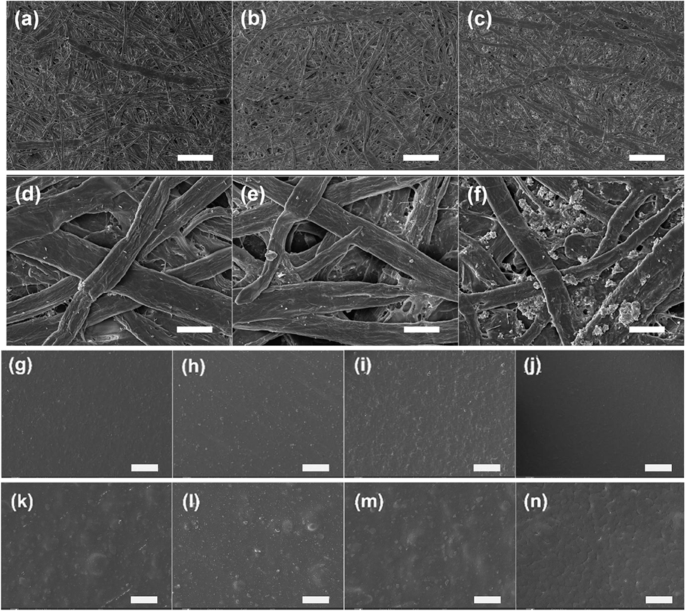

SEM images show that the three kinds of paper straws were composed of plant fibers with a high aspect ratio ( L / D ) (Fig. 2 a-f). At a larger magnification of 1000, heterogeneous particles were only observed on Pulp-3 (Fig. 2 d-f). Local magnification of the particles (at 5000 × and 20,000 ×) further revealed that these guest materials were present as elliptical particles (long axis = 0.4 − 2.0 μm and short axis = 0.2 − 1.0 μm) (Fig. S 2 ). These guest materials in Pulp-3 might be natural residues and/or additives to improve the straw performance. In addition, the paper straws exhibited a layer structure on the cross-section (Fig. S 3 ). The resultant void space was expected to intensify the capillary permeability of the paper straws, thus enhancing their water absorption and affecting the material’s mechanical strength in a wet state.

Morphology characterization of straw samples. Surface SEM images of Pulp-1, Pulp-2, and Pulp-3 at a magnification of a , b , c 100 and d , e , f 1000 with the scale bars representing 200 and 20 μm, respectively. Surface SEM images of PLA-1, PLA-2, PLA-3, and PP at a magnification of g , h , i , j 100 and k , l , m , n 1000 with the scale bars representing 200 and 20 μm, respectively

The surface of the PLA straws was nonporous and essentially smooth, similar to the PP straw (Fig. 2 g-j). The thicknesses of the polymeric straws (0.15 − 0.27 mm) determined from the cross-section SEM images (Fig. S 4 a-h) were consistent with the results from the vernier caliper measurement (0.15 − 0.23 mm). In addition, while we found a certain number of pores inside the PLA-1 straw (Fig. S 4 e), these pores were not interconnected. The surface of PLA-1 demonstrated a dense structure, indicating that the straw sample was likely capable of being resistant to water permeation. In comparison, the matrices of PLA-2, PLA-3, and PP samples were nonporous (Figs. 2 and S 4 ).

3.2 Water absorption and ion leaching

The clean water contact angles on the straw surfaces are shown in Fig. 3 a. Surprisingly, the contact angles of the paper straws under dry conditions were generally larger than those of the PLA straws, indicating that the surfaces of the paper straws were more hydrophobic. However, this finding was contradictory primarily to the poor consumer experience in using paper straws that often fall apart too quickly and may choke up people with disabilities (Danovich 2018 ; Szymkowiak and Blog 2018 ). To this end, we assume that the porous structure of paper straws (Fig. 2 ) should account for their poor feedback.

Hydrophobicity and ion leaching of drinking straws. a Clean water contact angles, b relative water absorption, and c leaching properties of paper, PLA, and PP straws. ∆ ρ indicates the change in solution conductivity

The relative water absorption rates (RA) demonstrated that paper straws were much more bibulous than PLA and PP straws (Fig. 3 b). Considering the surface morphology and hydrophobicity, we may infer that the porous structure matrix of paper straws inevitably led to a higher RA. In the study by Liu et al. ( 2020 ), alkyl ketene dimer was dosed at a content of 0.5 − 1.0% to impart water- and oil-proofing properties to cellulose microfibers; nevertheless, the molded pulp product had a water absorption of 59.4% following 1-h wetting. We further noted that the fiber creases on the straw surface gradually became obvious with an increase in the soaking time (Figs. S 5 - S 6 ), which might account for the deteriorated mechanical performance at an extended soaking time. In addition, the particles on the surface of the Pulp-3 disappeared at a higher soaking time, potentially attributing to the loss of surface hydrophobicity (Figs. S 5 c and S 6 c). Nevertheless, after soaking in water for 10 and 30 minutes, straws could sustain their structures. That is, we found no change in the FTIR images of PLA straws and minimal change in those of paper straws (Fig. S 7 ). These results indicated that the open structure of the paper straws made the liquid easily flow into the matrix’s inner part. In comparison, while tiny pores were observed on the cross-section of PLA straws, the dense structure of the polymers significantly alleviated the wetting effect. Minimal water absorption was therefore noted for PLA-1 (Fig. 3 b).

Ion leaching from the seven tested straws was first estimated by measuring the conductivity change of the impregnating solution after 10- and 30-min reactions (Fig. 3 c). Compared with PLA and PP straws, the paper straws resulted in significant ion leaching, which may account for the consumers’ criticism of the unpleasant taste in using paper straws. Considering the SEM results (Fig. 2 f), we inferred that the additive in the Pulp-3 straw might aggravate the leaching problem. Heavy metals, including Hg, Cr, Cu, Cd, and Pb, were not detected (< 0.01 μg/L) after 30-min immersion in water. The change of concentrations of Na + and Ca 2+ , the dominant dissolved metal ions, showed a similar trend as that of the solution conductivity (Table S 1 and Fig. 3 c). It has been reported that CaCl 2 (~ 1 mM) could produce a complex taste with bitterness predominant, which can explain the complex and unpleasant taste properties of paper straws in water (Lawless et al. 2004 ). While dissolved Zn was detected for paper straws (Table S 1 ), the leaching amount was negligible (~ 1.0 μg/g) in 30 min. To this end, it is supposed that the ion leaching from paper straws should have no human health risks, at least under the conditions tested in this study.

3.3 Evaluation of the dynamic mechanical properties

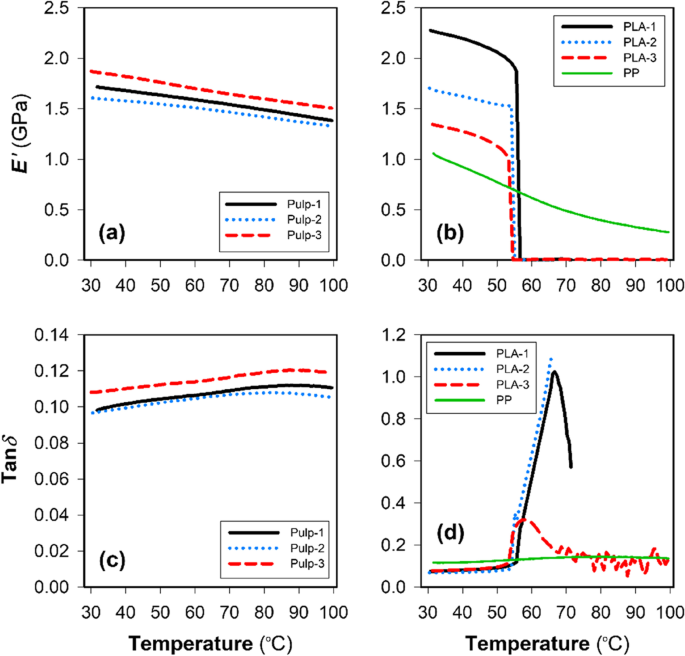

The temperature dependence of the storage modulus ( E ’) and loss factor (tan δ ) by employing DMA are depicted in Fig. 4 . As shown, E ’ of paper straws (1.7 ± 0.1 GPa) gradually decreased with an increase in the temperature (Fig. 4 a). In contrast, a falloff in the storage modulus was observed for all PLA samples at 50 − 60 °C (Fig. 4 b), which should be ascribed to the sudden increasing molecular mobility of the polymer chains (Singh et al. 2020 ). According to the information provided by the merchant (Table 1 ), it was indicated that the upper-temperature limit for PLA-3 was 80 °C, which was, however, not supported by the DMA results. Although the conventional PP straw demonstrated lower E ’ (i.e., lower stiffness, ~ 1.0 GPa) at the room temperature region as compared to paper and PLA straws, this petrochemical product exhibited a similar trend in E ’ change as the paper straws in the working temperature of 30 − 100 °C, indicating that the rigidity of the PP polymer matrix can sustain its versatilities under different scenarios (e.g., for a cold drink or hot coffee/tea).

Dynamic mechanical properties of straw samples. Storage modulus ( E ') as a function of temperature for a paper and b PLA and PP straws. Loss factor (tan δ ) for c paper and d PLA and PP straws

When the temperature is lower than the glass transition temperature ( T g ), the PLA matrix can maintain high storage modulus in a glassy state. As the temperature increases, the mobility of the frozen molecular chain increases, thus prompting the internal friction and loss modulus (Wen, et al. 2021 ). Therefore, T g values can be further analyzed with the change of the loss factor, Tan δ . Figure 4 c demonstrates that the variations of Tan δ of paper straws were minor over the temperature ranging from 30 °C to 100 °C, indicating that the glass transition of cellulose used in the paper straws was insignificant, at least under the conditions tested in this study. In comparison, the stiffness character of PLA straws changed remarkably when the temperature reached 54.6 − 56.6 °C (Fig. 4 d), which was recorded as T 0 . T g values of PLA-1 and PLA-3 indicated by the maximum Tan δ were 66.4 °C and 58.2 °C, respectively. Because PLA-2 became soft quickly and fractured at 66.2 °C, the T g value of PLA-2 could not be determined. In summary, the mechanical properties of PLA straws would significantly deteriorate at temperatures above ~ 55 °C. Considering the water absorption, ion leaching, and dynamic properties, we may infer that PLA straws perform similarly to traditional PP straws in drinking cold drinks and beverages at room temperature. However, using PLA straws in hot drinks (such as hot tea and coffee) may create an unpleasant consumer experience.

3.4 Biodegradation in natural soil tests

Following a 15-days landfill of straw samples (Fig. S 8 ) under the condition that the soil temperature and humidity were maintained within a reasonable range, fungi were found on all paper straws (Fig. 5 a). After 30 days of the landfill, the biodegradation was more evident for the paper straws (Fig. S 9 ). In contrast, there was an insignificant change in the shape or the surface of PLA and PP straws after the natural soil test for 30 days (Fig. 5 a and S 9 ). We further carried out a quantitative calculation for the mass loss during the burial experimentation. As shown in Fig. 5 b, the mass loss of the paper straws increased to 1.84% − 3.75% after being buried for 30 days. The biodegradation rate of the paper straws tested in this study was lower compared to the pulp products in the literature (Ma et al. 2022 ), probably due to the use of hydrophobic additives (Fig. 3 a) that could limit the bacterial access to the straw surface to initiate the biodegradation process. While PLA straws have been indicated as “biodegradable” alternatives to PP straws, their degradation requires hydrolysis at a high temperature (such as 60 °C in composting). Results of this study further indicate that when the temperature (e.g., 25 ± 2 °C in the burial tests) is significantly lower than T g , the movement of the molecular chains inside the polymer is restricted, which may contribute to the non-biodegradable character in natural soil. PLA products can demonstrate good stability in the natural environment and are not easily degraded by microorganisms in the ground (Karamanlioglu and Robson 2013 ; Heyde 1998 ). Given that most PLA straws are not separated, collected, and treated under composting conditions, they may behave as refractory products such as PP that have posed environmental threats.

Evaluation of biodegradability. a Optical images of straws after being buried in soil for 15 days, and b mass loss following 15- and 30-days in natural soil

3.5 Survey and consumers’ feedback

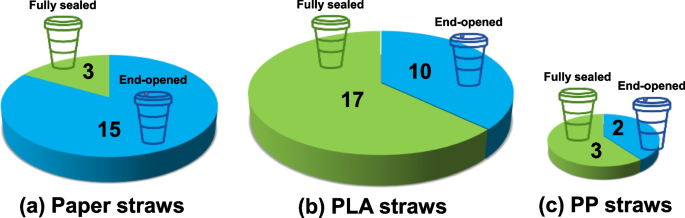

Sixty-eight participants took part in this survey, with all questionnaires retrieved after the consumer testing. The number of PP straws served to the panelists (i.e., 5) was smaller than the number of paper or PLA straws (i.e., 10-11), because this questionnaire focused on consumer feedback on biodegradable straws. The numbers of questionnaires collected for paper and PLA straws demonstrated a uniform distribution (Table S 2 ). In addition, 52.94% of the tested beverages contained toppings, with 63.89% of the subset containing large-size toppings such as tapioca balls (particle size 5 − 8 mm) and 36.11% with small-size, soft toppings (e.g., jelly and pudding). Moreover, 47.06% of the beverage containers were capped with an open-ended lid (Fig. S 10 a-c), with the others fully sealed (Fig. S 10 d). Since only 2.94% of the consumers chose beverages of a medium (40 ± 5 °C) temperature, we expected that the consumer testing would not reflect the poor mechanical property of PLA products at a high temperature.

With regard to the consumer response to “ease of intubation/piercing the cover (Q10 in Table 2 , a score ( S avg ) of 5 and 1, respectively indicating the best and worst experience)”, the results showed that there were differences among the liking of biopolymer and conventional straws. Consumers preferred the easy use of PP ( S avg : 5.0) to PLA ( S avg : 4.74) and paper ( S avg : 4.16) straws. However, the difference between paper and PP straws (representing the state-of-the-art product in performance) was less than one point in the hedonic scale. In contrast to criticism, we found that the participants showed relatively high tolerance of using paper straws to pierce the lid of beverages. Unsurprisingly, only 10 participants suffered from problems such as “incidents of straw fracture” (i.e., Q11 in Table 2 ), including 6 using paper straws and 4 using PLA straws. The failure ratio of Pulp-3 (16%) was significantly lower compared to Pulp-1 (34%) and Pulp-2 (50%), which should be ascribed to the higher storage modulus of Pulp-3 (Fig. 4 a) and potentially the use of additives (Fig. 2 f). As such, these findings may indicate that (i) the paper straws used in this study have better mechanical properties in the dry state, which is consistent with the DMA results (Fig. 4 a) and/or (ii) undiscovered factors ducked the differences between PLA (or PP) and paper straws.

To investigate the underpinning mechanism for the consumers’ feedback, we carried out a taxonomy analysis of the surveying results. For Q10, 50 participants chose the highest score of 5, including 18 from paper straws (and 6 for each type), 27 from PLA straws (and 8, 10, and 9 for PLA-1, PLA-2, and PLA-3), and 5 from PP straws. When the data were further classified according to the sealing methods ( i.e. , “open-ended lid” or “fully sealed on top” as shown in Fig. S 10 ), the difference in the liking of the straws was noted. As shown in Fig. 6 a, the consumers scored high for open-ended beverages employing paper straws. In contrast, PLA and PP straws were not subject to this limitation, indicating that these products are versatile (Fig. 6 b and c). Only consumers using paper straws suffered unpleasant experiences (including three participants who scored “3” and one who scored “1”) when drinking fully sealed beverages. To this end, we inferred that the problem of paper straws in piercing could be concealed by changing the sealing method of beverages. When only the “fully sealed on top” dataset was retrieved for analysis, S avg for paper straws dropped to 3.46 while that for PLA straws remained at 4.70. Likewise, 90% fracture of straws (Q11 in Table 2 ) occurred in drinking fully sealed beverages. The results of this study justified that introducing a differentiated packaging method could significantly alleviate the limitation of inserting paper straws into beverages.

Taxonomy of the best experience (score = 5) in intubation in response to the sealing methods. The rating of 5 received from consumers using a paper, b PLA, and c PP straws. The sealing methods included “fully sealed (green)” or “end-opened (blue)” as shown in Fig. S 10 . Data from Q10 in the questionnaire (Table 2 ) were retrieved for analysis

Correlation analysis of results of Q12 (describing their straw mouthfeel) in Table 2 was conducted in response to variables including the material type of the straws ( x 1 , where x 1 = 1 for paper straws, 2 for PLA straws and 3 for PP straws) and beverage temperature ( x 2 ). The multiple linear regression results (Table S 3 , F > significance threshold of 0.002) showed that the beverage temperature had a negative impact ( β x1 = − 0.39, p = 0.12) on the consumers’ liking of the straw mouthfeel. Similar to a recent study on filtered water (Jonsson et al. 2021 ), our work indicated that PLA straws had a better mouthfeel than paper straws ( β x2 = 0.64, p = 0.002). This was probably ascribed to the ion leaching of paper straws. Furthermore, Q13 in Table 2 discussed the softening and unpleasant flavor problems during drinking, and correlation analysis was carried out using variables of the material type of the straws ( x 1 ) and drinking duration ( x 2 ). The logic value was set to 1 for the presence of “softening and unpleasant flavor” while the other was 0. The statistic output in Table S 4 demonstrated that the multiple linear regression model was reliable with adjusted R 2 = 0.37 and F value (19.88) that was more significant than the threshold (2.25E − 07). Specifically, a longer drinking duration may result in the “softening and unpleasant flavor” problem though the relationship was not significant ( p > 0.1). In comparison, the material type played a vital role ( p = 4.15E − 08) in determining the water absorption properties of straws. Paper straws suffered severe “softening and unpleasant flavor” problems compared to PLA straws as β x2 = − 0.48 (Table S 4 ). Consumers had the worst experience using Pulp-1, probably because Pulp-1 had the highest water absorption rate though the material surface demonstrated the highest hydrophobicity. As such, we assume that the water absorption rate might be the most crucial parameter influencing the consumer liking of the straw’s texture and flavor, at least under the conditions tested in this study.

The overarching goal of this consumer survey was to determine whether the properties of products (e.g., mechanical strength, water absorption, and ion leaching) would affect the consumer liking (e.g., mouthfeel, taste, flavor, and ease of inserting) and, finally, the willingness to purchase. After removing the non-sensitive survey questions, including “Q14, failure of topping intake”, “Q16, straw damage by incident bite” and “Q17, any lipstick residue on the straw” (Table 2 ), we took the results of Q10 − Q13 in the questionnaire as the new variables, and “Q18 whether the straw performance would affect purchase willingness of beverages?” as the dependent variable to conduct the correlation analysis (Table S 5 ). The logic value was set to 1 for “Yes” while 0 represents “No”. The straw mouthfeel (Q12) and softening problem (Q13) had insignificant impacts on the consumer willingness to purchase ( p = 0.40 and 0.48, respectively). In contrast, the ease of inserting (Q10) and the incident of straw fracture (Q11) were the crucial parameters ( p = 0.09 and 0.03). Especially, a straw that can be easily inserted into a beverage without fracture is conducive to consumer purchase (Table S 5 ).

4 Discussion

In the raw material market, the price of PLA is higher than the pulp (Raghavan 2019 ). However, the average cost of paper straws purchased in this study (0.180 RMB per unit) was higher than the PLA straws (0.172 RMB per unit), which was mainly ascribed to the differences between their thicknesses (Table 1 ). Manufacturers may increase the dose of raw materials in producing paper straws. While this practice has imparted superior mechanical properties to the products (Fig. 4 ), the inevitable consequences included a higher price that had impaired the comparative advantage of paper straws in cost and a more substantial water absorption capacity due to the larger void space on the cross-section. Since this property was closely related to paper straws’ softening/dissolving problem, the manufacturers should further consider the solution by compacting the matrix structure or adding waterproof fillers (Ma et al. 2022 ).

The feedback from the consumers indicated that the most significant factors influencing the purchase willingness were the ease of inserting and the incident of straw fracture. A recent study has proposed new natural fiber materials for catering, which demonstrated excellent performance and could be more profitable than PLA (Liu et al. 2020 ). While merchants may optimize the packing method (e.g., employing an open-ended design) to address the intrinsic limitation of paper straws, consideration should be given to the potential problems. For example, the world is currently in the epidemic period of COVID-19. In addition to the risk of beverage spill of the open-ended design, there is a high possibility of contamination. Furthermore, the results of this study showed that the biodegradation of PLA straws was negligible in soil burial tests (Fig. 5 ). According to the questionnaire (Q19 in Table 2 ), over 50% (37 of 68) participants had incomplete knowledge of the composition and environmental impacts of the straws they used, which would challenge the sustainable management of the biopolymers at the end of their lives. Continued public education is, therefore, essential to close the knowledge gap in this field.

In this study, we systematically analyzed the physicochemical properties of straws and their consumer feedback. Note that a few conclusions may be contrary to the common sense. For example, we found that paper straws may have extremely good hydrophobicity under dry conditions. Nevertheless, our research still has some limitations, including the limited sample number used for comparison and the relatively narrow consumer population. DMA tests provided important information on sample mechanical properties at different temperatures, though further work under varying conditions ( e.g. , dry vs. wet conditions) would be essential to assess the change of straw performance in use. To prompt the wider application of bio-based straws, more attention should be paid to improving the straws' penetration properties while ensuring their degradability. In addition, we have demonstrated the importance of packaging methods. Suitable packaging is conducive to improving the consumption experience, thus promoting the replacement of plastic straws.

5 Conclusions

While hydrophobization improved the surface hydrophobicity of the paper straws, the open structure with void space prompted water penetration and absorption, which might affect the taste of the drink. In contrast, the compact polymer matrices of all PLA straws prevented mass exchange in their use for drinking. Since the PLA straws showed similar anti-degradation properties as the PP straw, a clear message on a separate collection should be provided. The participants had a comparable liking of paper and PLA straws to insert into a drink, however, the intrinsic difference was covered up by the open-ended capping for beverages. In contrast to the perceptions, the mouthfeel and the straw softening had minor impacts on consumers’ willingness to purchase. A biodegradable straw that can be easily inserted into a drink with no fracture may be conducive to the revenue of merchants.

Availability of data and materials

All data generated or analysed during this study were included in the article. (We confirmed the data used to support the findings of this study were available from the corresponding author upon request).

Akiyama M et al (2012) Package Design of Ready-to-Drink Coffee Beverages Based on Food Kansei Model-Effects of Straw and Cognition Terms on Consumer’s Pleasantness. Food Bioprocess Technol 5:1924–1938. https://doi.org/10.1007/s11947-011-0527-5

Article CAS Google Scholar

Andrady AL (2011) Microplastics in the marine environment. Mar Pollut Bull 62:1596–1605. https://doi.org/10.1016/j.marpolbul.2011.05.030

Aravinthan et al (2019) Fourier transform infrared spectroscopy (FTIR), Raman spectroscopy and wide-angle X-ray scattering (WAXS) of polypropylene (PP)/cyclic olefin copolymer (COC) blends for qualitative and quantitative analysis. Polym Bull 76:4259–4274. https://doi.org/10.1007/s00289-018-2599-0

Auras RA, Lim L-T, Selke SE, Tsuji H (2011) Poly (lactic acid): synthesis, structures, properties, processing, and applications. Wiley, Hoboken

Baulch S, Perry C (2014) Evaluating the impacts of marine debris on cetaceans. Mar Pollut Bull 80:210–221. https://doi.org/10.1016/j.marpolbul.2013.12.050

Chokshi, N. How a 9-year-old boy's statistic shaped a debate on straws , https://www.nytimes.com/2018/07/19/business/plastic-straws-ban-fact-check-nyt.html (2018)

Danovich, T. Why People With Disabilities Want Bans On Plastic Straws To Be More Flexible , https://www.npr.org/sections/thesalt/2018/07/11/627773979/why-people-with-disabilities-want-bans-on-plastic-straws-to-be-more-flexible (2018)

Drever MC et al (2018) Are ocean conditions and plastic debris resulting in a ‘double whammy’ for marine birds? Mar Pollut Bull 133:684–692. https://doi.org/10.1016/j.marpolbul.2018.06.028

Ebnesajjad S, ed Sina Ebnesajjad (2014) In surface treatment of materials for adhesive bonding, 2nd edition. William Andrew Publishing, Waltham, pp 39–75

Fahim I, Chbib H, Mahmoud HM (2019) The synthesis, production & economic feasibility of manufacturing PLA from agricultural waste. Sustainable Chem Pharm 12:100142

Article Google Scholar

Foundation, E. M. The new plastics economy: rethinking the future of plastics , https://ellenmacarthurfoundation.org/the-new-plastics-economy-rethinking-the-future-of-plastics (2016)

Project, G. C. Global carbon budget , https://www.globalcarbonproject.org/carbonbudget/index.htm (2022)

He Y, Inoue Y (2000) Novel FTIR method for determining the crystallinity of poly(ε-caprolactone). John Wiley & Sons, Ltd 49:623–626

CAS Google Scholar

Heede R (2014) Tracing anthropogenic carbon dioxide and methane emissions to fossil fuel and cement producers, 1854–2010. Clim Change 122:229–241. https://doi.org/10.1007/s10584-013-0986-y

Heyde M (1998) Ecological considerations on the use and production of biosynthetic and synthetic biodegradable polymers. Polym Degrad Stab 59:3–6

Hinterstoisser B, Salmén L (1999) Two-dimensional step-scan FTIR: a tool to unravel the OH-valency-range of the spectrum of Cellulose I. Cellulose 6:251–263. https://doi.org/10.1023/A:1009225815913

Jimenez S, Domingo A, Brazeiro A, Defeo O, Phillips RA (2015) Marine debris ingestion by albatrosses in the southwest Atlantic Ocean. Mar Pollut Bull 96:149–154. https://doi.org/10.1016/j.marpolbul.2015.05.034